The Whole Product Must be Tested

23 Dec 2021

The Whole Product Must be Tested

Question:

I would like to ask for your expert advice regarding testing an Emergency Batten for 61000-3-2. The Emergency Batten contains, EM Controlgear +240V LED Driver. The emergency Control gear has a power less than 5W (no 61000-3-2 limits) and 240V LED Driver.

If the 240V Batten is tested to 61000-3-2 it will pass, but if the EM Batten is tested while EM Controlgear is connected it will fail because of the Harmonics from the Low power EM Driver.

My question is, do you think it is possible to make a justification document that EM Controlgear is exempted from 61000-3-2 and test 240V Batten on its own?

Response:

No. When selling a product, compliance with 61000-3-2 applies to the product itself – which in your case means the Control Gear integrated with the 240V LED Driver as a complete functional unit. The solutions available to you are:

Either: design or purchase a 240V LED Driver that has low-enough mains harmonic emissions so that – when combined with the emissions of your Control Gear – the whole Emergency Lighting Batten complies when tested to IEC 61000-3-2, or

Or: fit a harmonic filter to the mains inlet of the Emergency Lighting Batten so that the whole Emergency Lighting Batten complies when tested to IEC 61000-3-2.

An extreme example of this sort of issue occurs with customised test equipment cabinets.

Some manufacturers buy a number of different rack-mounted instruments or computers and install them in rack cabinets to meet the particular needs of different customers. They may only make a few, perhaps just one, of each type of cabinet.

They often make two mistakes:

They mistakenly assume that – because they are CE marked – each of the rack-mounted instruments or computers must therefore be fully compliant with all EMC standards (including 61000-3-2) and Safety standards (e.g. IEC/EN/UL 60950-1 or its replacement, 62368-1)

They mistakenly assume that because all the instruments or computers in the cabinet comply with the relevant EMC and Safety standards, therefore the completed cabinet must also comply with EMC and Safety.

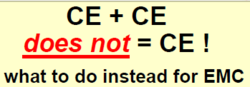

This is called the “CE + CE = CE approach”, and it is dead wrong!

Just like your situation, the product they sell must itself comply with the limits in 61000-3-2 – but because it contains a number of different test instruments or computers each of which will probably be close to the limit themselves (so that their manufacturers maximise their profits) – the rack cabinet itself (which is the product being made and sold) will probably fail 61000-3-2 due to the build-up of the harmonic currents from all of the test instruments or computers it contains.

In general, such cabinets cannot be sold as legally-EMC-compliant products without special measures, such as harmonic filters.

And for safety, the leakage currents from each of the test instruments or computers will probably be low-enough individually – but when a number of them are installed in the rack cabinet their leakage currents will build up too, quite probably resulting in to hazardous levels for the cabinet as a whole!

In general, such cabinets cannot be sold as legally-Safety-compliant products without special measures, such as high-integrity protective earthing in their installations.

For more on why CE + CE does not equal CE for EMC, see: https://www.emcstandards.co.uk/emc-systems-installations-2000-part-6-ce-plu or buy my more up-to-date training course: https://www.emcstandards.co.uk/ce-ce-does-not-ce-what-to-do-instead-fo.

For more on why CE + CE does not equal CE for Safety, buy my training course: https://www.emcstandards.co.uk/the-safe-design-of-electrical-equipment-lvd-com.

Get more from EMC Standards

EMC Standards is a world-leading resource for all things EMC and EMI related. Our website is packed full of both free and paid-for content, including:

- Online quiz

- Webinars

- Training quiz

- And much more!

Electromagnetic Engineering (EMgineering) is the basis for proven good design practices for signal integrity (SI), power integrity (PI), and the control of EMI emissions and immunity (EMC).

Our aim is to help people learn how to more quickly and cost-effectively design and manufacture electronic equipment (products, systems, installations, etc.) to meet functional (i.e. SI/PI) specifications and conform to EMC standards, directives and other requirements.

Such equipment should benefit from reduced warranty costs and financial risks, whilst improving uptime, competitiveness and profitability.

We also cover basic good electrical safety engineering; and the Risk Management of Electromagnetic Disturbances / EMI, whether for Functional Safety or other types of risk.

Join EMC standards TODAY!