The Overlooked Impact of Annex B in EMC Standards: Are We Over-Testing?

01 Nov 2024

This article was originally published by the same author on Linkedin.

This is about EN 61000-4-6: 2023 Annex B (Informative). Are product committees actually reading and understanding the basic standards? Probably not. Are EMC test laboratories over-testing and failing products as a result? They probably are!

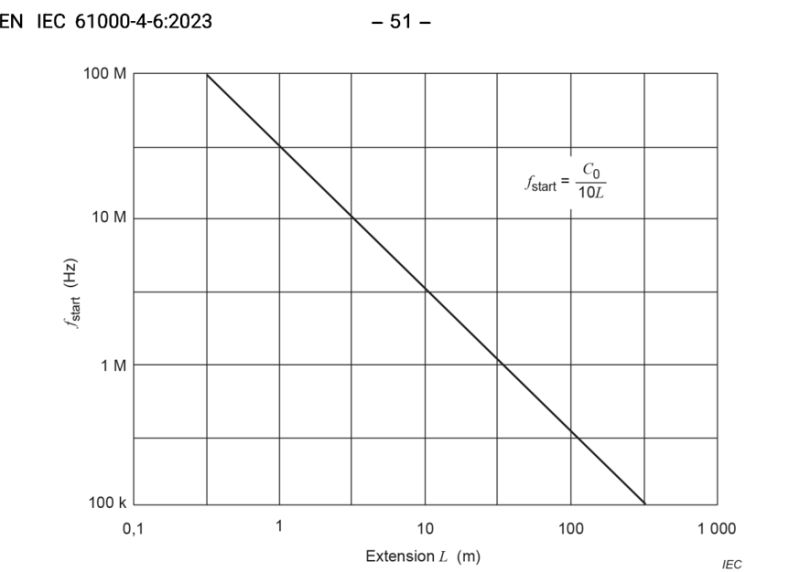

Annex B deals with the application of the test when the EUT and cabling has a total length that isn’t sufficiently long enough to be an effective receptor of interference. The cut off frequency is given by the speed of light divided by 10 times the overall EUT and cable length combined. The Annex makes the reasonable argument that below the cut off frequency the energy transferred via the cable to any EUT interface wouldn’t be sufficient to interfere with the EUT.

In the case of a battery-operated laptop with a keyboard on a 4 m cable (as illustrated in the Annex), the cutoff frequency is 6.6 MHz. For frequencies below 6.6 MHz, adding a CDN at 30 cm from the EUT interface port and applying an RF interfering signal at 3/10 Vrms is, according to the basic standard, unnecessary, as there would never be sufficient energy coupled to that cable.

Now, I’ve been around and know most product standards (and their versions over the years), and not one of them adopts this guidance. Yes, there’s the typical 3 m cable length statement, but here we have a main test basic standard offering specific guidance "for product committees," and yet, for over 20 years, this guidance in the basic test standard has been ignored.

For product designers and manufacturers, this can have a massive impact on design cost, time to market, and test lab expenses.

Get more from EMC Standards

EMC Standards is a world-leading resource for all things EMC and EMI related. Our website is packed full of both free and paid-for content, including:

- Online quiz

- Webinars

- Training quiz

- And much more!

Electromagnetic Engineering (EMgineering) is the basis for proven good design practices for signal integrity (SI), power integrity (PI), and the control of EMI emissions and immunity (EMC).

Our aim is to help people learn how to more quickly and cost-effectively design and manufacture electronic equipment (products, systems, installations, etc.) to meet functional (i.e. SI/PI) specifications and conform to EMC standards, directives and other requirements.

Such equipment should benefit from reduced warranty costs and financial risks, whilst improving uptime, competitiveness and profitability.

We also cover basic good electrical safety engineering; and the Risk Management of Electromagnetic Disturbances / EMI, whether for Functional Safety or other types of risk.

Join EMC standards TODAY!