Reducing the Ambient EM Noise for Benchtop EMI Troubleshooting

29 Mar 2023

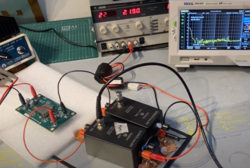

Over the past few years, several equipment manufacturers have launched affordable benchtop spectrum analyzers and pre-compliance EMC equipment (such as LISNs, CDNs, RF current probes & RF amplifiers, etc) that are useful for several aspects of EMI troubleshooting and pre-compliance work.

These units are often priced between $1000 and $3000 (USD). A small-to-medium enterprise (SME) can therefore have its own benchtop EMC pre-compliance set-up at a total cost of $5000. This is a smart investment, considering a visit/re-visit to the EMC test house can easily cost a company thousands of dollars and many weeks of lead time.

Ken Wyatt has many blog articles on this subject, including [1], and his “EMC Troubleshooting Trilogy ” [2] are a great piece of work detailing the low-cost EMI test set-ups. Another useful resource is Mayerhofer’s “How to correctly use spectrum analyzers for EMC pre-compliance tests” [3]. Armstrong has many free online resources to download [4], and I highly recommend his articles on near-field probing [5].

This article discusses an important factor of a benchtop pre-compliance EMC set-up that is not covered in previous articles and is worth your consideration.

Ambient EM Noise Check

The first thing you’ll run into when testing conducted or radiated emissions on your benchtop is the ambient electromagnetic (EM) noise. Typically, the ambient noise sources are from:

- A dirty/polluted mains network will affect the conducted emission results, even though the LISN unit has some form of filtering. For radiated emission tests using a far-field antenna, extension leads, or mains cables plugged into the mains socket will radiate the noise, adding noise floor to the ambient scan.

- The power supply unit used for testing has its own conducted and radiated noise. Unless you have a linear power supply, or a battery or an expensive low-noise power supply, you will measure the noise generated from the power supply itself, as it is usually an isolated switched mode power supply, meaning the common mode noise is similar between the AC input side and the DC output side.

- Noise sources nearby, including laptops, 3D printers, and more.

- Lighting in the room.

- FM and TV broadcast transmitters, cellular phones, walkie-talkies, and more.

The seemingly radiated noise sources (such as lighting and FM) can couple to the wires in the benchtop EMC set-up; thus, the spectrum analyser can also pick them up in the conducted emission test.

Suppressing Ambient Noise

Being aware of ambient noise is the first step towards efficient EMI troubleshooting. We can then use the following methods to reduce the ambient EM noise.

- Location, location, location – If you are one of the lucky companies that have a low-noise environment, congratulations! But most engineering companies are located in relatively noisy areas, so selecting a dedicated room for EMC troubleshooting becomes essential. A basement/underground is often preferred as they have some shielding capability, especially for mobile signals and FM radios.

- Check the mains network power quality using an isolated HV probe connected to an oscilloscope. If the FFT analysis shows a significantly high noise level, consider purchasing some good-quality filters. Note that most commercial off-the-shelf filters are designed for filtering noise between 150 kHz and 30 MHz, which is often sufficient for performing a conducted emission test. You may not have enough attenuation to suppress the noise in the lower frequency range (below 1 MHz, the insertion loss of the filter may not be good enough). In this case, consider building your own filter or purchasing specially-made filters.

- If the benchtop set-up is for measuring conducted emissions using a power supply unit. Use multiple ferrite cores on both the input cables and the output cables. My favourite ferrite combo is a two-turn Fair-rite 75 material (to suppress lower frequency noise) with a two-turn Fair-rite 31 material (or Würth 74271251 to suppress the noise between 10 and 30 MHz).

- Switch off equipment/devices nearby, and if possible, switch off the lights.

How much is enough?

Generally, the ambient noise level must be at least 6 dB below the limit line for benchtop EMC pre-compliance tests. In practice, an ambient noise floor 20-30 dB below the limit line can often be achieved for conducted emission tests using the ambient noise suppression methods we introduced previously. However, achieving a “quiet” noise floor in certain bands is difficult without a chamber/EMC tent.

For radiated emission tests, when a small antenna is used, because of the antenna's physical size, in the lower frequency range (30MHz to 130 MHz), you will find the ambient noise floor higher than the limit line once you factor in the antenna factor (AF). In theory, connecting a low-noise broadband amplifier to the antenna can reduce the noise floor. In reality, however, it is often difficult to achieve a low-noise floor. A full-size antenna has a much better AF in the lower frequency range. Given a relatively EM quiet environment, one may achieve a noise floor 6 dB below the limit line.

If you just want to troubleshoot an existing EMI issue, i.e. you do not care about the resolution bandwidth (RBW) in your set-up, a trick I often use is to lower the RBW to 1kHz or even 100 Hz. By doing so, the noise floor can be reduced, and the noise from the DUT can then be observed. Once you see the noise, you can work on the mitigation solution.

You can also watch the following Youtube videos or a video demonstration:

I am also part of the Training Workshop team at the upcoming EMC and CI 2023 event in Newbury, England in May - click here to see the full programme!

References

[1] K. Wyatt, " Troubleshooting EMI on your bench top," EDN, 19 May 2014. [Online]. Available: https://www.edn.com/troubleshooting-emi-on-your-bench-top/

[2] K. Wyatt, "EMC Troubleshooting Trilogy," Available: https://www.amazon.com/gp/product/B0B4KB8YJS

[3] M. Mayerhofer, “How to correctly use spectrum analyzers for EMC pre-compliance tests,” [Online]. Available: https://www.tekbox.com/product/AN_spectrum_analyzers_for_EMC_testing.pdf

[4] https://www.emcstandards.co.uk/emcacademy

[5] K.Armstrong, “Cost Effective Near Field Probing,” [Online]. Available:https://www.emcstandards.co.uk/files/cost-effective_close-field_probing_1_of_2_nov_20_2013_1.pdf

Get more from EMC Standards

EMC Standards is a world-leading resource for all things EMC and EMI related. Our website is packed full of both free and paid-for content, including:

- Online quiz

- Webinars

- Training quiz

- And much more!

Electromagnetic Engineering (EMgineering) is the basis for proven good design practices for signal integrity (SI), power integrity (PI), and the control of EMI emissions and immunity (EMC).

Our aim is to help people learn how to more quickly and cost-effectively design and manufacture electronic equipment (products, systems, installations, etc.) to meet functional (i.e. SI/PI) specifications and conform to EMC standards, directives and other requirements.

Such equipment should benefit from reduced warranty costs and financial risks, whilst improving uptime, competitiveness and profitability.

We also cover basic good electrical safety engineering; and the Risk Management of Electromagnetic Disturbances / EMI, whether for Functional Safety or other types of risk.

Join EMC standards TODAY!