Mains filters might not perform to spec, and can even amplify noise, in real life

24 Jan 2019

A recent query on mains filtering raised some issues I thought you might find interesting.

A system integrator had purchased an item of commercial equipment that as usual had a switching power converter and a mains filter. His system had to meet a military conducted mains emissions specification that set limits down to 1kHz, and above 150kHz the equipment’s emissions were comfortably under the limit, but at 80kHz there was a peak that was way, way over the top. This problem arose because the equipment was been designed to meet a commercial EMC specification, so had been fitted by its manufacturer with a mains filter that was only designed to kick-in above 150kHz, when tested in an EMC lab with a LISN (sometimes called an Artificial Mains Network, AMN). The switching power converter operated at 80kHz, with harmonics at 160kHz, 240kHz, 320kHz, 400kHz, etc., etc., which all had to be filtered to meet the commercial limits above 150kHz. But the emissions at its 80kHz fundamental were not attenuated and might even have been amplified, by the filter!

Some military EMC test specifications might not impose tougher limits or levels than

commercial test spec’s, but they always cover wider frequency ranges. So, where a

commercial conducted emissions spec might cover 150kHz to 30MHz, the equivalent military spec might cover 1kHz to 100MHz. A commercial radiated emissions test spec might cover 30MHz to 6GHz, while a military equivalent might cover 10kHz to 18GHz.

How can mains filters amplify?

Mains filters are combinations of inductors and capacitors, and so will always resonate at some frequencies. If damping resistors are added to tame the resonances, the best that can be achieved is 0dB at the resonant frequencies: i.e. no gain – but no attenuation either. LISNs and AMNs present differential-mode (DM) and common-mode (CM) source impedances of 50 Ohms resistive, just as are used in the CISPR 17 filter test method, to match the 50 Ohms resistive terminations used by RF/EMC test equipment such as spectrum analysers, signal generators, RF power amplifiers, and network analysers.

When designing a filter to have good attenuation above 150kHz, resonances that cause gain are allowed to occur in the frequency range below 150kHz, and these can of course cause problems below 150kHz.

This is one reason why compliance with conducted emissions standards should never be taken to mean that EMI problems will not be caused in real life. It is worth remembering that the EMC Directive requires unacceptable EMI not to be caused at any frequency, regardless of the frequency ranges covered by the harmonised EMC standards. Even worse, real-life mains supply source impedances vary widely over 50Hz to 30MHz – DM impedances vary at least from 2 Ohms to 2,000 Ohms, and although they are predominantly resistive below a few hundred Hz, above 1kHz DM impedances are complex: having inductive and capacitive components whose behaviour depends on the frequency. And in real life all CM impedances are complex, with a range greater than 2 Ohms to 2k Ohms, and are most unlikely to ever be resistive. Not only that, but in real applications the values of the DM and CM source impedances, and their phase angles, will vary throughout the day according to what other mains-powered equipment is plugged-in and/or operating at a given time. These non-50-Ohm complex source impedances interact with the inductors and capacitors in the mains filters, almost always causing larger resonances than with the idealised 50 Ohm resistive impedances used in laboratory testing. Also, these real-life complex mains impedances can shift a filter’s resonant frequencies to higher than 150kHz, and/or create new resonances above that frequency.

It is best to assume that the performance promised by mains filters’ datasheets bear little resemblance to the performance they will achieve in real-life applications, especially at frequencies below 5MHz.

See my 2005 article on mains filters and its regularly updated training course version for how to deal with these issues, and also how to deal with the significant degradations in filter attenuation that can be caused by excess voltages, high currents, and high operating temperatures.

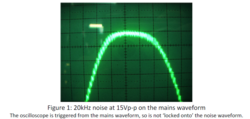

I once had to deal with a new machining centre in a factory that put 15Vp-p on the mains at 20kHz when it was operated (see Figure 1), causing more than half of the other equipment in the factory to malfunction. 20kHz was the 5th harmonic of the machining centre’s 55kW variable-speed motor drive (VSD), but the fundamental and harmonics below the 5th were not a problem, even though they would be expected to have higher levels.

This pointed to a resonance in the interaction of the filter with its complex source impedance causing a significant gain (rather than attenuation) at 20kHz.

See Figure 1: 20kHz noise at 15Vp-p on the mains waveform

The oscilloscope is triggered from the mains waveform, so is not ‘locked onto’ the noise waveform. The solution turned out to be quite quick and easy. The 55kW VSD was a Siemens type, but the manufacturer of the machining centre had chosen to use a cheaper mains filter than the one Siemens recommended for use with their drive. The cheaper mains filter allowed the machining centre to pass emissions tests above 150kHz, but the manufacturer had only thought of passing the tests – not about the fact that the VSD’s rather high-power noise emissions at its switching frequency of 4kHz and its harmonics – 8kHz, 12kHz, 16kHz, 20kHz, etc. – might cause EMI problems in real-life at frequencies below 150kHz. Fitting the filter recommended by Siemens for the motor drive reduced the 20kHz noise to below 1.5Vp-p, didn’t cause any other noises to become significant, and solved the problem in the factory. (I found it interesting that the Siemens filter was about the same size but weighed about three times more than the cheaper one originally fitted. It has generally been my experience that for the same package size, heavier filters seem to work better in real-life than lighter ones regardless of their datasheet specifications. But this is merely a passing observation, and I certainly don’t offer it as any kind of guidance!)

Custom design is the best approach

Returning to our system integrator’s problem: the best approach is to get the commercial equipment’s supplier to provide a customised version that meets the tougher (military) conducted emissions specification. After all, in such situations we are usually only dealing with small numbers of systems, so the equipment supplier should not have to worry unduly about the cost of the filters. Some manufacturers (and, to be fair, some of their system integrator customers too) don’t ‘get’ this, wasting a great deal of time and money trying to reduce the BOM cost of the low-volumecustom version, as a result possibly even suffering financial losses when they should have been making profits.

For example, simply replacing the low-cost commercial-grade mains filter in the equipment with a costly high-performance military-grade filter (e.g. from MPE, Total EMC Products, or other experienced military filter manufacturers) can usually achieve a quick and low-cost solution – from the system integrator’s viewpoint.

It doesn’t hurt, either, that these military-grade filters should prove much more reliable over the many years, even many decades, of system operation. (I understand that commercial grade mains filters generally need replacing after 15 years or so.)

Please note that, to obtain the EMC benefits of using such high-spec filters, special

attenuation should be paid to achieving very low-impedance multi-point RF bonding to the appropriate RF Reference (often confusingly called ‘grounding’ or ‘earthing’).

See my 2005 article on mains filters and its regularly updated training course version for details on this.

Some military filter connectors also provide guidance, such as this from MPE (scroll down to find it). In my experience, this can usually be achieved quite quickly and easily – if (once again) we don’t get hung up on the BOM cost of the custom equipment – and also as long as we don’t care whether the end result looks pretty.

Why not simply add another filter in series? I generally don’t recommend doing this. (Well, not any longer, at any rate!) It seems that it should be straightforward enough, but filters connected in series inevitably interact with each other, usually resulting in lower overall performance than expected. Their interactions can even cause resonances that make the series combination of two mains filters much worse than either filter on its own! I have seen this happen in real life, when I added an external mains filter to a VSD that had an internal mains filter, and the problem emissions got even worse. After spending some time trying to find where I had gone wrong, and beginning to start doubting my own sanity, I remembered reading that simply connecting good filters in series can result in poor overall attenuation, even gain. I realised that I was experiencing this for the first time.

It is for exactly this reason that designers of multi-stage mains filters take great care to avoid unwanted resonances between their filters’ internal stages.

When adding a packaged filter in series with the mains filter of a purchased equipment – if we know enough about the detailed designs of the two filters concerned, we should be able to perform similar analyses to choose a combination that acts pretty much as the sum of its parts. Obtaining sufficient design information on the filters to begin our analysis of their probable interactions, might prove to be more difficult than anticipated. Many people would probably attempt to solve the problem by trial-and-error; adding different samples of packaged filters in series with the problem equipment until a good enough result is obtained. I have done this many times in the past!

A problem with this approach can be assembling/installing the additional packaged filter in a way that does not compromise the filtering performance of the overall assembly, and without voiding the warranty of the supplied equipment. But even if we do manage to do this successfully when testing with a LISN or AMN, when

connected to the complex and time-varying non-50-Ohm mains source impedances present in the real operating environment we might still find that performance of the series connected filters is not as good as required.

Buying commercial equipment and bolting filters and shielding to it to meet tougher EMC specifications is a costly and time-consuming process, with many traps for the unwary! (Similar undesirable interactions can arise when adding extra shielding to a shielded equipment.) It is generally much better overall, to simply contract the supplier in the first place to provide equipment that has replaced its mains filter that was just-about good enough for the commercial EMC test spec, with one designed by experts to be just-about good enough for the military EMC test spec (especially its wider frequency ranges).

At first sight it usually doesn’t seem like this approach will be the most timely and cost effective, but by avoiding the unexpected and (usually) unpredictable interactions discussed above it provides the system integrator with more robust and reliable project timescales.

And by helping to avoid very unpleasant surprises from occurring from time-to-time,

especially to integrators who cut corners on EMC and feel pleased with themselves for having managed to ‘get away’ with it (so far!), this approach helps ensure profitability is maintained over the medium and longer terms.

« Back to Blog